PRODUCER: McCoig Materials, LLC

PRODUCTS USED: UltraFlo® 2000, UltraFinish A1

Marathon Oil Corporation began construction on its estimated $1.9 billion Heavy Oil Upgrade Project (HOUP) at the Detroit Refinery, following air quality permit approval from the Michigan Department of Environmental Quality (MDEQ). The project will increase refining capacity from 102,000 to 115,000 barrels per day (bpd), including 80,000 bpd of heavy oil. The increase in capacity will add more than 400,000 gallons of clean transportation fuels to the market daily. Refinery upgrades include a 28,000 bpd delayed coker unit that coverts asphalt-like material into fuel components and petroleum coke. This enables the processing of heavy Canadian Crude oil into higher quality products like gasoline and diesel.

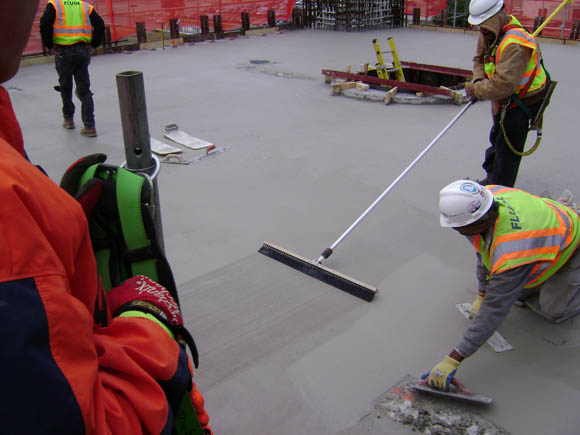

Fluor Corporation handled engineering, procurement, and construction. The project required concrete that stayed below 160°F and strength gains of 1,000 psi per day for the first three days, allowing nearby piling within 24 hours. Flour also requested Self Consolidating Concrete (SCC) for safer, easier placement. The concrete producer, with help from Premiere Concrete Admixtures and SCC specialist Mike McKown, successfully developed a mix incorporating 70% GGBFS that met all specifications.