Detroit, MI

Marathon Oil Coker Plant

Marathon Oil Corporation has begun construction of the estimated $1.9 billion heavy oil upgrading project at its Detroit refinery, following issuance of an air quality permit by the Michigan Department of Environmental Quality (MDEQ).

With expected completion in late 2010, the Heavy Oil Upgrade Project (HOUP) will increase the refinery’s total capacity from 102,000 barrels per day (bpd) to 115,000 bpd, which will include an additional 80,000 bpd of heavy oil capacity. The increased refining capacity will supply more than 400,000 additional gallons of clean transportation fuels a day to the marketplace.

The refinery upgrades include adding a new processing unit called a delayed coker. The 28,000 bpd coker converts asphalt-like material into liquid petroleum fuel blend components and petroleum coke (a coal-like substance). It also will allow the refinery to thermally convert and upgrade heavy Canadian crude oil into higher quality products such as gasoline, diesel and petroleum coke.

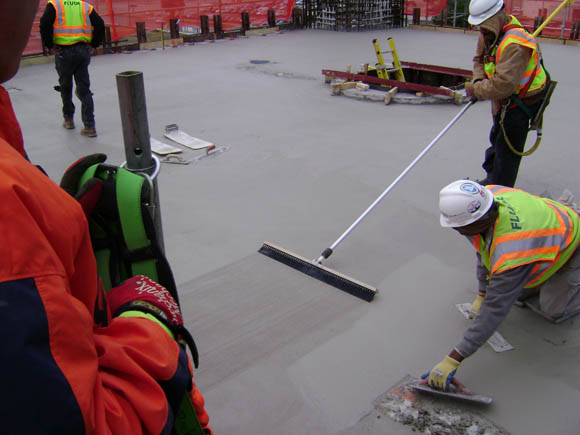

Fluor Corporation will provide integrated engineering, procurement and construction services for the refinery project. Construction challenges include mass concrete with a peak temperature restrictions of 160oF. In addition Fluor requested that the ready mix producer provide them with a mix that met the temperature requirements but also produce strength gains of 1000 PSI per day for 3 days. This was needed to drive pilings in close proximity to the pour in less than 24 hours.

Fluor wanted to pursue an application that promoted safety and ease of placement. A representative of Fluor had investigated Self Consolidating Concrete and requested that producer design a SCC Mix that would meet all of the parameters. The Concrete Producer enlisted the help of Premiere Concrete Admixtures LLC out of Pioneer Ohio. Mike McKown Regional Sales Manager and SCC specialist evaluated their materials and was able to successfully design a mix which incorperated 70% GGBFS in test batches that fulfilled Fluor’s request.